We are a trusted supplier of high-quality aluminium and metal products, offering precision-manufactured materials, consistent quality, and dependable delivery for industrial, engineering, and fabrication needs.

Jaiman Metalloys LLP

We are a trusted supplier of high-quality aluminium and metal products, offering precision-manufactured materials, consistent quality, and dependable delivery for industrial, engineering, and fabrication needs.

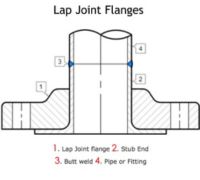

Stainless Steel Lap Joint Flange

Alloy Steel, Carbon Steel Lap Joint Flange

1-Lap Joint Flange | 2-Stub End | 3-Butt weld | 4-Pipe or Fitting

| Size | 1/2″ (15 NB) to 48″ (1200 NB) |

|---|---|

| Standards | ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings |

| Pressure Ratings |

Class 150, Class 300, Class 400, Class 600, Class 900, Class 1500, Class

2500 PN6, PN10, PN16, PN25, PN40, PN64 |

| Carbon Steel Slip-on Flanges |

ASTM A105 / A105N, A350 LF1, LF2 CL1/CL2, LF3 CL1/CL2, A694 F42, F46, F48, F50, F52, F56, F60, F65, F70, A516 Gr.60, 65, 70, RST37.2, C22.8 (Spectacle Blind Flange, Spacer Ring / Spade Flange) |

| Stainless Steel Slip-on Flanges |

ASTM A182 F202, F304 / 304L / 304H, F316 / 316L / 316H / 316Ti, F310, F321, F904L |

| Alloy Steel Slip-on Flanges | ASTM A182 F1, F5, F9, F11, F22, F91 |

| Special Alloy Slip-on Flanges | Duplex, Super Duplex, Nickel Alloys |

| Flange Face Type | Flat Face (FF), Raised Face (RF), Ring Type Joint (RTJ) |

| Coating / Surface Treatment |

Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold & Hot Dip Galvanized |

| Value Added Services | CNC Machining, Customised Flanges |

All products are carefully packed using secure and industry-standard packaging methods to ensure complete protection during storage and transportation. For export consignments, robust wooden case packaging is used in compliance with international shipping standards. Each item is permanently marked with material grade, heat or lot number, size, specification, and our registered trademark to ensure full traceability. Custom marking and special packaging options are available on request.

Quality is ensured through strict inspection at every stage of the manufacturing process, from raw material sourcing to final dispatch. All products are checked for compliance with international standards such as ASTM, ASME, MSS, DIN, EN, and JIS. Third-party inspection agencies can be arranged on request to verify material test reports, dimensions, and overall quality conformity.

Comprehensive test certification is provided to ensure full material traceability and quality assurance. Manufacturer Test Certificates in accordance with EN 10204 / 3.1 are supplied along with raw material certificates. Additional documentation such as 100% radiography test reports and third-party inspection reports are available on request to meet project and customer requirements.